| Plastic Mould Steel 塑料模具钢 |

|

| 440C ESR High Carbon, High Chrome Martensitic Stainless Steel |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

Mo |

| 1.10 |

1.00 |

1.00 |

17.00 |

0.75 |

|

|

| Nearest Equivalent |

| AISI |

JIS |

WN(werkstoff number) |

| 440C |

SUS440C |

1.4125 |

|

| Delivery condition - annealed 210 - 250HB |

|

| Steel Properties |

| Martensitic stainless steel, high wear resistance,Moderate corrosion resistance |

|

| Application |

| Jig & ficture, mould insert, wear part etc |

|

| Heat Treatment |

| Solf Annealing |

900°C, cooling in furnace |

| Hardening |

1000°C - 1050°C, quench in forced air |

|

|

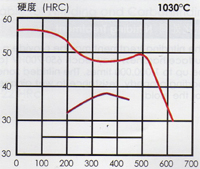

| 440C ESR Tempering Graph Hardening at 1030°C |

|

|

| 420 ESR Plastic Mould Steel |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

V |

| 0.38 |

0.8 |

0.5 |

13.6 |

0.3 |

|

|

| Nearest Equivalent |

| AISI |

JIS |

WN(werkstoff number) |

| 420ESR |

SUS420J2 |

1.2083 |

|

| Delivery condition - annealed 210HB |

|

| Steel Properties |

Electro slag refining (double remelted)

High Chromium plastic mould steel, good corrosion and good wear resistance |

|

| Application |

| Plastic injection mould, transfer mould and Jig & fixture etc |

|

| Heat Treatment |

| Solf Annealing |

770°C, cooling in furnace |

| Hardening |

1020°C - 1030°C, quenching in forced air |

|

|

| 回火图 Tempering Graph HRC |

|

|

| P20 Prehardened Plastic Mould Steel |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

S |

| 0.36 |

0.3 |

0.9 |

1.85 |

0.015 |

|

|

| Nearest Equivalent |

| AISI |

JIS |

WN(werkstoff number) |

| P20 |

PDS3 |

1.2311 |

|

|

| Steel Properties |

| Hardened & tempered plastic mould steel between 290-320HB |

|

| Application |

| Plastic mould steel, mould base, fixture, component etc |

|

| Heat Treatment |

| The increase the service life of mould up to 800,000 times, you may harden the pre-hardened steel by means of quenching and low-temperature tempering. For quencing, firstly preheat for 2-4 hours under 500-600°C and then maintain the temperature at 850-880°C for a period of time (at least 2 hours). Put the steel into the oil for cooling 50-100°C and then remove it from the oil for air cooling. After quenching, the hardness may be high up to 50-52HRC. To avoid crack, please immediately carry out low-temperature tempering treatment at 200°C. After tempering, the hardness may be kept over 48HRC. |

|

| Relation between tempering temperature and hardness |

| 回火温度(°C) Tempering Temperature |

200 |

300 |

400 |

500 |

550 |

600 |

650 |

| 硬度值(HRC) Hardness |

48 |

46 |

44 |

39-40 |

37-38 |

33-34 |

26-27 |

|

|

| Nitriding Treatment |

| The nitriding treatment may be provide a surface structure of high hardness. After nitriding, the surface hardness may reach 650-700HV (approx, 57-60HRC) and the service life of the mold may be up to 1,000,000 times. The nitrided zone features in compact and smooth structure, while the parting property, resistance to wet air and resistanc to alkali corrosion will be highly enhanced for the mold. |

|