| Cold Work Tool Steel 冷作钢 |

|

| 2379 High Carbon, High Chrome Steel |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

Mo |

V |

| 1.5 |

0.25 |

0.30 |

11.5 |

0.80 |

0.80 |

|

| ALSO SUPPLY MACHINING PLATE COMPLETE WITH HEAT-TREATMENT + SUB - ZERO |

|

|

| Nearest Equivalent |

| AISI |

JIS |

WN(werkstoff number) |

| D2 |

SKD11 |

1.2379 |

|

| Delivery condition - annealed 220HB |

|

| Steel Properties |

High carbon and high chromium, air hardening cool work tool steel

High abrasive wear resistance and good toughness |

|

| Application |

| Blanking & stamping dies, trimming & forming dies, drawing dies and cutting tools etc |

|

| Heat Treatment |

| Solf annealing - 860°C, quenching in forced air or warm oil |

|

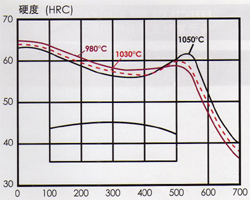

| 回火图 Tempering Graph HRC |

|

|

| 2510 Oil Hardening Steel |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

W |

Mo |

V |

| 0.9 |

0.30 |

1.20 |

0.50 |

0.50 |

0.13 |

0.12 |

|

|

| Nearest Equivalent |

| AISI |

JIS |

WN(werkstoff number) |

| 01 |

SKS 3 |

1.2510 |

|

| Delivery condition - annealed 210HB |

|

| Steel Properties |

Low alloy oil hardening tool steel

High machinability,medium toughness, resistance to wear |

|

| Application |

| Blanking & stamping dies, bending dies, gauges, measuring tools and coining dies etc |

|

| Heat Treatment |

Solf annealing - 780°C, cooling in furnace

Hardening - 800°C - 850°C, quenching in warm oil |

|

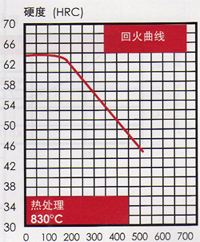

| 回火图 Tempering Graph HRC |

| 试样直径为 25mm 50mm |

| 淬硬温度为 830°C |

|

|

| WTC53 High Performance Tool Steel |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

Mo |

V |

| 1.00 |

1.05 |

0.35 |

8.00 |

2.00 |

0.2 |

|

|

| Nearest Equivalent -- DC53 |

| Delivery condition - annealed 220HB |

|

| Steel Properties |

High Carbon, Cr-Mo-V, air hardening tool steel

High wear resistance and good toughness |

|

| Application |

Punch dies, drawing dies which are complicated in shape and high precision

Deep drawng and cold forging dies |

|

| Heat Treatment |

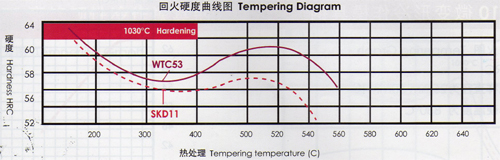

| 回火图 Tempering Graph |

|

|