| High Speed Steel 高速钢 |

|

| SKH 9 High Speed Steel |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

Mo |

W |

V |

| 0.85 |

0.3 |

0.3 |

4.0 |

5.0 |

6.0 |

2.0 |

|

|

| Nearest Equivalent |

| AISI |

JIS |

WN(werkstoff number) |

| M2 |

SKH9 |

1.3343 |

|

|

| Application |

Drill, tap, end mill, milling cutter etc

Punch and dies for cold and hot working |

|

| Heat Treatment |

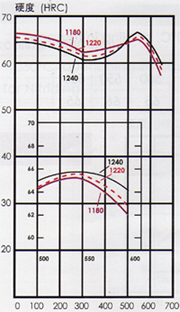

| Harden at (Temper at 550°C) |

1200°C |

1150°C |

1100°C |

| Hardness (HRc) |

62-64 |

61-63 |

57-59 |

|

|

| 回火图 Tempering Graph |

|

|

| SKH 55 High Speed Steel With Co |

|

| Chemical Composition (analysis %) |

| C |

Si |

Mn |

Cr |

Mo |

V |

W |

Co |

| 0.92 |

0.40 |

0.30 |

4.10 |

5.00 |

1.9 |

6.4 |

4.8 |

|

| ALSO SUPPLY MACHINING PLATE COMPLETE WITH HEAT-TREATMENT + SUB - ZERO |

|

|

| Nearest Equivalent |

| AISI |

JIS |

WN(werkstoff number) |

| M35 |

SKH 55 |

1.3243 |

|

| Delivery condition - annealed HB269 |

|

| Steel Properties |

High speed steel with 4.8% of Cobalt

High hardness, high red highness, good toughness |

|

| Application |

| Milling cutter, twist drill, tap, profile cutting tool, turning tool etc |

|

| Heat Treatment |

Solf annealing - 770°C-810°C, cooling in furnace

Harden at 1200°C |

| Temper at (°C) |

300 |

400 |

500 |

550 |

580 |

| Hardness (HRc) |

61 |

62 |

65 |

66 |

65 |

|

|

| 回火图 Tempering Graph |

|

|